Quality inspection items

Quality inspection project process

We have professional quality inspection equipment. Adhering to the principle of ensuring customer satisfaction, we carefully handle each product with a sense of social responsibility.

1.Humidity and heat resistance aging performance test

Set specific temperature and humidity conditions and duration for the test.

2.Negative pressure sealing test

Start the vacuum machine, evacuate the sealed tank to the preset negative pressure (such as -0.08 MPa) and maintain it for a certain period of time.

3.High-temperature cooking performance test

Seal the bag opening with a heat sealing machine and place it in the high-temperature steaming pot. Set the steaming conditions.

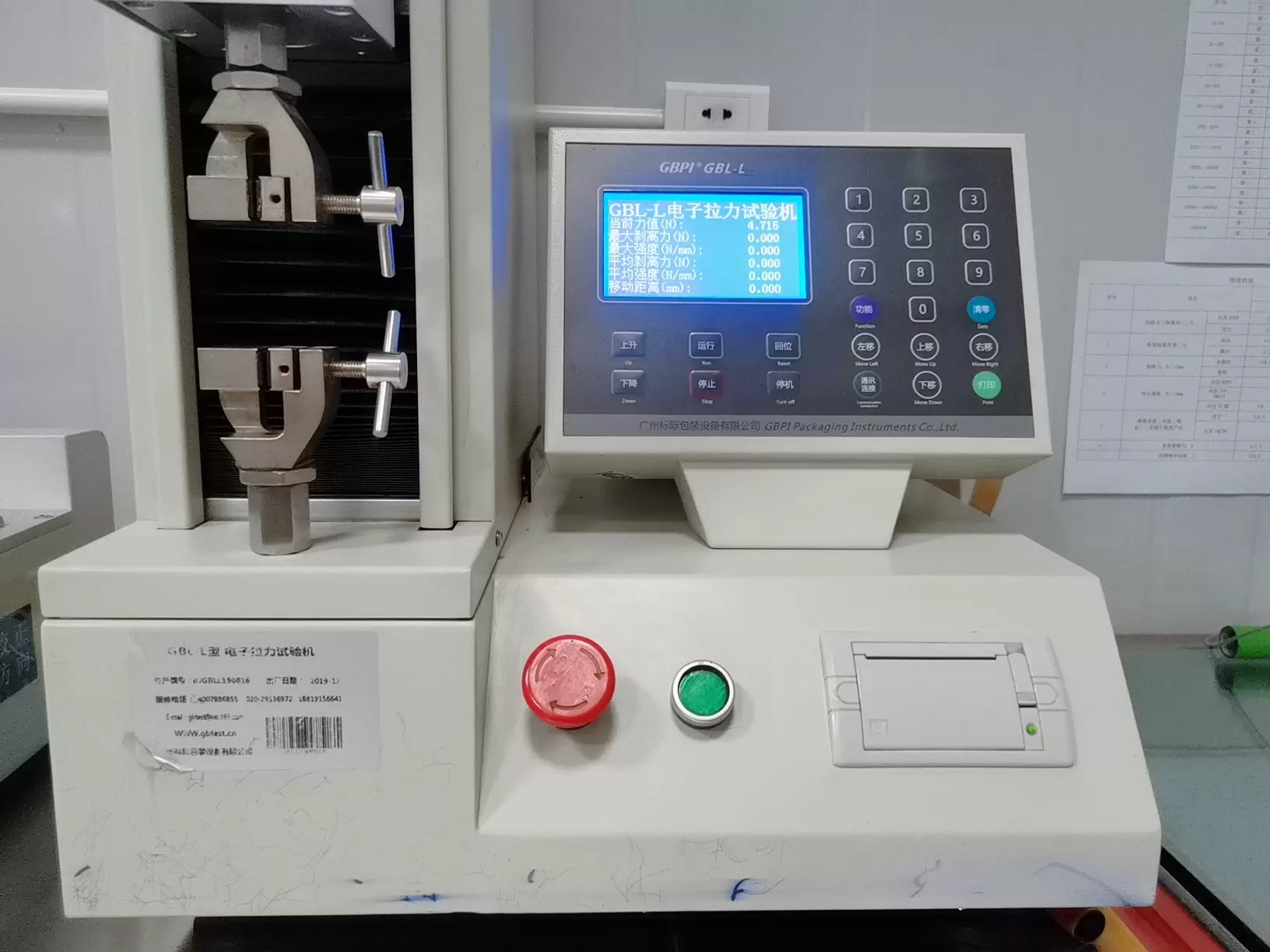

4.Peel strength test

Manually peel off a small section of the composite layer, then stretch it at a constant speed, and record the separation value of the composite layer.

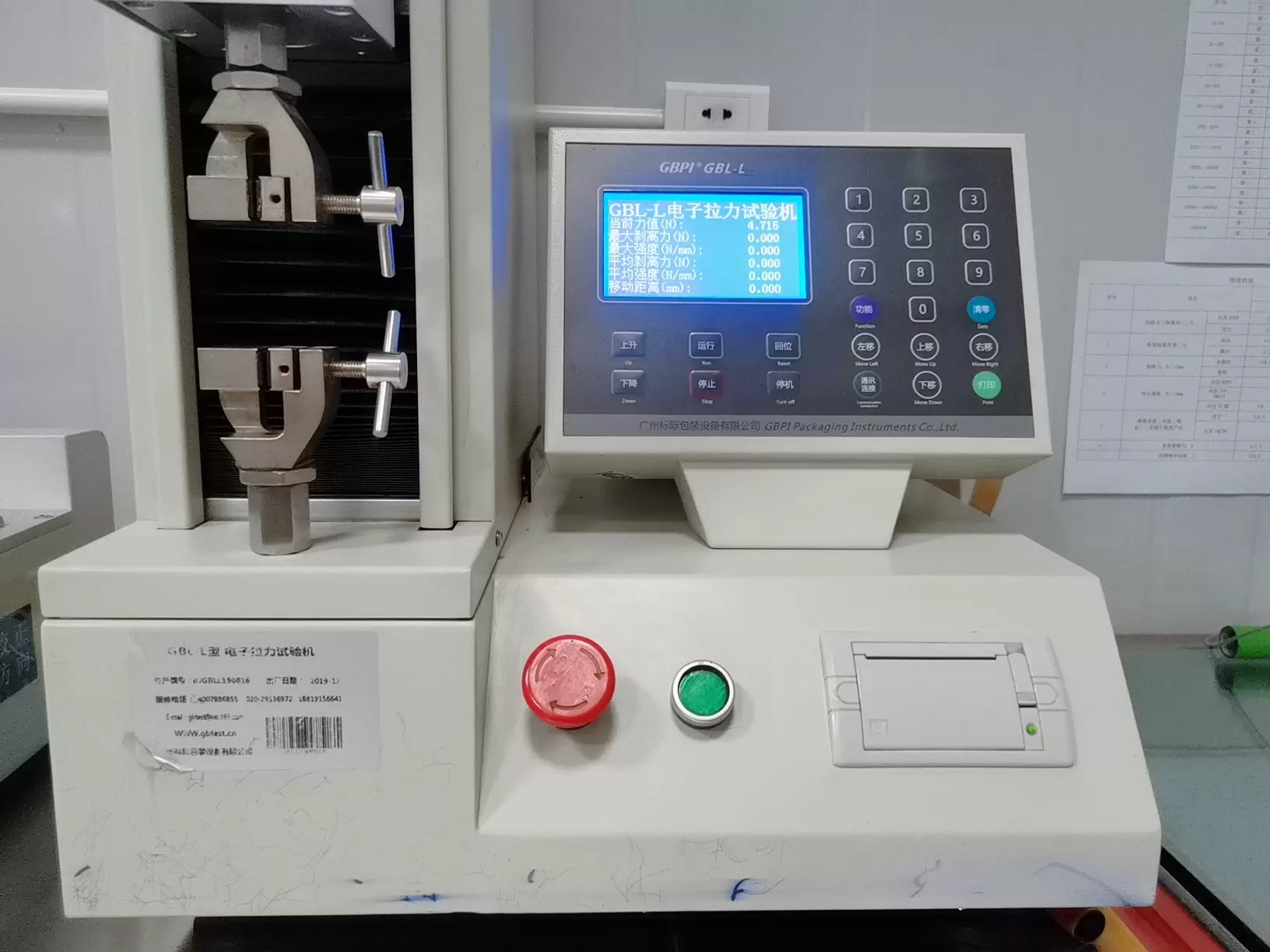

5.Heat sealing strength test

Place the unsealed ends of the strip sample on the fixture, so that the edge seal is in the middle. Stretch until the edge seal is torn.

6.Hot sealing parameter process verification

Identify the optimal combination of temperature, pressure and time that can achieve the best sealing effect.

7.Impact toughness test

By systematically increasing the quality of the dart heads or the drop height, the energy required to break 50% of the samples was measured.

8.Dynamic friction coefficient test

Place the film sample flat on the instrument platform, and move the dedicated slider forward uniformly on it.

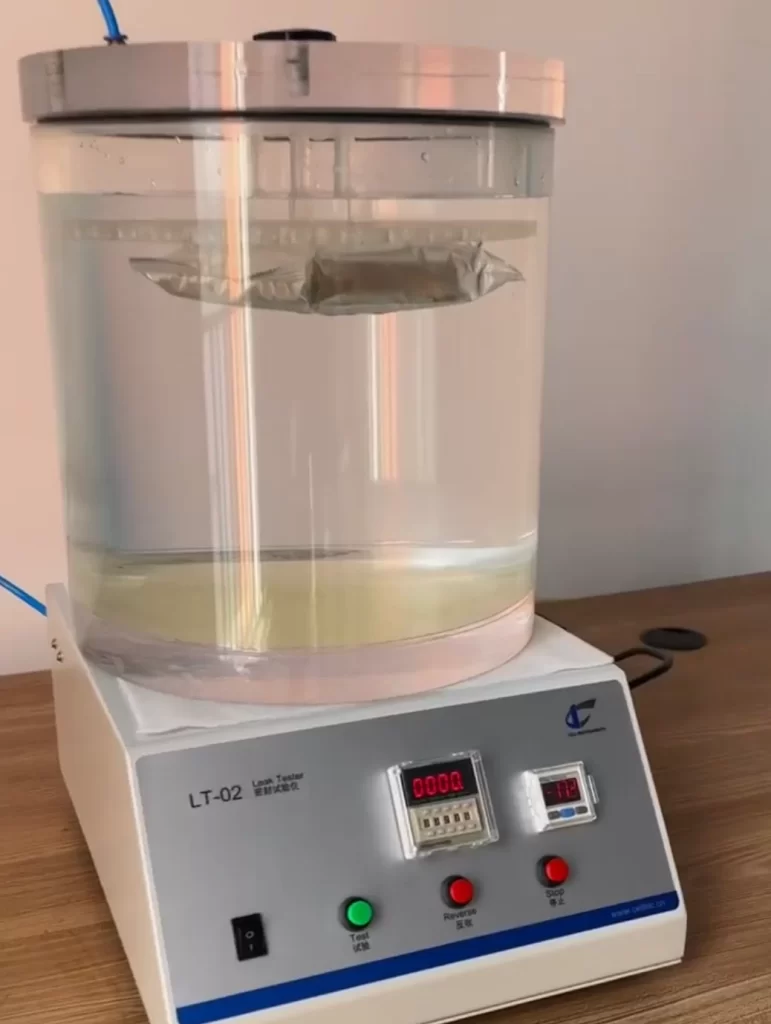

9.Positive pressure sealing test

Immerse the inflated bag in water or monitor the pressure retention through sensors.

10.Inspection machine

Automatically identify and mark defects such as stains, knife marks, registration deviations, holes, and edge sealing foreign substances.